I've been in my role, with Melink Corporation as an Intelli-Hood® sales engineer just over 1.5 years. I want to ensure it's understood that I am certainly no expert in the "Construction World,” but I do have tangible experience. This article's content is based on my first-hand experiences, real-world applications I've dealt with, and conversations I've had. Thus, these opinions are largely subject to my own with some additional input from outside articles and research.

My first week into this role was a mix of emotion, to say the last. It was during this week that my manager (whom I see as an industry expert and mentor) expressed to me something along the lines of "Eric, you're dealing with one of the toughest verticals Melink works within [New Construction]. I'll be honest with you - you're going to learn so much, but you're really going to have to learn to love frustration."

Yes, you likely share my same sentiment — skepticism, surprise, and curiosity — though it didn't take long to understand what he meant. I was "christened" nearly the very first project. Long story short, despite our product being hard-specified by the hired designing mechanical engineer, our product was ultimately "value engineered" for a cheaper alternative. Echoing my feelings earlier, I was surprised, curious, and frustrated. I became aware of the "Achilles heel" of the New Construction world — the bidding process, which is influenced by cost. Cost is, and always has been, the deciding factor in mostly all aspects of a new build project. It makes sense until you dig deeper.

Everyone Is Guilty

Even the product manufacturers should hold themselves accountable in this regard; they/we are just trying to play the "game" and stay in business. In his article “People Are Cost-Driven with Kitchen Equipment but There's an Adage of Buy Cheap, Buy Twice,” Andrew Seymour interviewed a chef by the name of Hayden Groves. Groves is quoted as saying some buyers are too “Excel spreadsheet-driven” and end up trying to shave off costs when it might not be the right move for the business.

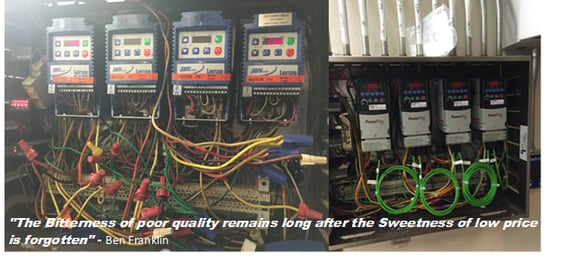

Firsthand, I've seen this happen, as explained earlier. Our Intelli-Hood controls can often be eliminated for a cheaper alternative that cannot do the same thing, thus not producing the same results

as our technology. This decision is often made without any discussion or pragmatic decision process.

Who makes this decision? Ultimately, it should be the owner or whomever holds the checkbook and it often is; in this case, I understand. The owner can do what he/she wants to do. Unfortunately, often it's a "bidder" who is trying to win the project by competing solely on cost. Again, I want to reiterate that this doesn’t happen every time, but it does happen way more than it should.

Yes, I am saying that if a trusted designer hypothetically specifies a Rolls-Royce, then you'll likely see most bidders price out a Toyota Camry (Toyotas are great vehicles - I own one!). Yes, they both have engines and four wheels, but they are uniquely different and have glaringly different features,

components, and values. Without going down this rabbit hole, I'll just say it’s the principle of

the matter…that matters.

A Shared Frustration

Attending an industry conference this past week, I had the chance to sit down with

consultants and manufacturers. This exact discussion was brought to the table as a point of frustration for the consultants. They share my frustration! Construction bidding/approval is a broken process and research supports this argument.

Consulting-Specifying Engineers provided the top 10 HVAC systems and building automation system (BAS) challenges. The top challenge, comprising 79% of respondents, is the inadequate budget for a good design. Conversely, this same research shows that 96% of specifying engineers can agree that product quality is paramount when comparing products, above all else; these are the engineers that are hired for their expertise to ultimately design and specify products to accompany the design, to meet an owner's and/or architect's goals.

Yet, here we are. A battle between the desire to specify based on quality but ultimately being sold on what is cheapest. So, how does a whole industry change? Perhaps by “eating the elephant, one bite at a time” as they say.

One often overlooked and unquestioned factor is that of aftermarket and post-install support. It’s imperative that we all make sure to mention our product's warranties and service/support on the front end of the process, as the lack of either could potentially be a major headache on the backend. If I never mentioned Melink’s warranties/service in my discussions, they would never get asked about; this is shocking. A 2016 McKinsey study proves that service and support reign most important in terms of purchasing factors

In addition, Groves also harps on warranties/support. He said, “You should look for a manufacturers’ warranty, too. If a manufacturer gives you a minimum standard of a year, but somebody else gives you

five years, that’s a huge belief in that piece of equipment."

Speaking of Rolls Royce…

"The quality is remembered long after the price is forgotten."

- Sir Henry Royce of Rolls Royce

Sources

- Pelliccione, Amanda. “2019 HVAC & Building Automation Systems Study.” Equal Opportunity Publications, Inc, 16 Jan. 2019, bt.e-ditionsbyfry.com/publication/?i=559857.

- Seymour, Andrew. “People Are Cost-Driven with Kitchen Equipment but There's an Adage of Buy Cheap, Buy Twice.” Foodservice Equipment Journal, 30 Nov. 2018.

- McCrory, Wilson, et al. “How to Unlock Growth in the Largest Accounts.” www.mckinsey.com, McKinsey & Company, Sept. 2016.

Submitted by Eric Tanner