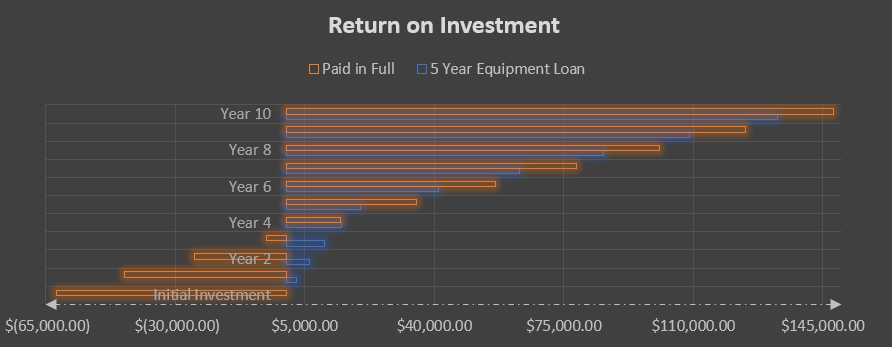

No investment should ever result in a negative cash flow. Nor should it take forever to achieve a healthy ROI on the initial money you spend. This is important for any business or organization, especially those that operate on very small margins (i.e., restaurants). That shouldn’t stop you from making investments in your business, provided they pay for themselves in the coming years. Such is the case with demand control kitchen ventilation systems (DCKV). Those who install DCKV in their commercial kitchen spaces can often see immediate positive cash flow, and many systems pay for themselves outright, in as little as a year.

Whether you’re operating on razor thin margins or are simply concerned about the initial costs of a DCKV system, you can put to rest the fear of not getting a healthy ROI out of your DCKV investment.

What is a Demand Control Kitchen Ventilation System?

For those unfamiliar with how DCKV systems work, they essentially transform your traditional kitchen hood into an automated, intelligent ventilation system. Using optic and smart temperature sensors, DCKV systems actively monitor your cooking activities, automatically activating and adjusting the variable frequency drive (VFD) that controls the speed of the kitchen hood exhaust fan.

In short, they only run your kitchen hood’s ventilation system when needed and as intensely as needed, rather than running full speed 100% of the time.

How does this system create a cash positive journey that pays for itself? It’s a mixture of unique design, smart technology, and simple energy savings.

Reducing Energy Costs

Food sales and service businesses have some of the highest energy costs per square foot. Other businesses that have commercial kitchens in their buildings (hospitals, educational buildings, hospitality, etc.) will also be able to attest to the energy costs of running their kitchen spaces. Part of this is due to the inefficiencies of commercial kitchen hoods and exhaust systems. These static systems are designed to constantly run, pushing air out of the facility during all operation hours.

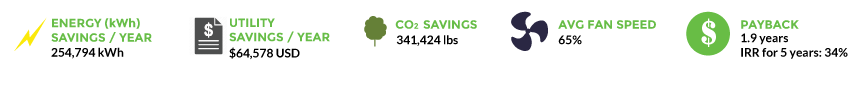

While these exhaust systems are essential for operation, they are often wasteful. These systems do not need to be running all the time, just like air conditioning and heating sources do not need to be constantly pushing warm or cold air into a space. DCKV systems like the Melink Intelli-Hood® use optic and smart temperature sensors to monitor the level of cooking activity, automatically adjusting your fans to operate at full speed when necessary. This significantly reduces energy costs, saving tens of thousands of kWh by not running exhaust systems constantly and by helping keep heated or cooled air in spaces longer.

DCKV systems help reduce:

- HVAC costs (Save 30%-40% on conditioned air)

- Electricity costs (Save up to 66%-78% on fan energy)

- KiloWatt hours (kWh)

- Net heat load (kBTU)

- Exhaust volume (CFM)

- Reduce CO2 emissions

These energy savings produce a positive cash journey the minute the system is installed in any commercial kitchen, resulting in savings that begin to pay back the investment over time. This case study shows how Miami University saved approximately $65,000 on utility costs in a single year after installing Intelli-Hood®, helping them achieve a LEED Silver rating.

Melink Intelli-Hood® can be installed on new construction builds or retrofitted into most existing kitchen exhaust systems. It's time that you made an investment in your commercial kitchen that pays for itself.