Supermarkets have been operating around the clock during the pandemic to keep their patrons well-stocked with the essentials. One thing that many people (besides maybe the engineers who build them) don’t appreciate is how these stores are specifically designed to keep products safe and shoppers happy.

Grocery Store Micro-Climates

A well-designed grocery store starts with understanding the individual micro-climates that are found throughout each store.

For example, the fresh produce section is typically kept at a higher humidity so that fruits and vegetables do not wilt under dehydration. Refrigerated sections, on the other hand, maintain low humidity levels to keep condensation off the cases. The difference in humidity between these zones drives air between them, bringing significant moisture directly to the refrigeration section, where this is unwanted. Because there are often no physical walls preventing forced air, airflow requirements become even more important to get right. The utilization of outside air (OA) and the recirculation of air already in the store is the key to balancing this obstacle.

Outside air and its circulation ensures that the air within a supermarket is well-mixed for the benefit of the product and the customers. The problem, however, comes in determining how this air is brought in.

Climate Control Methods within Grocery Stores

There are multiple ways to control the climate within a facility.

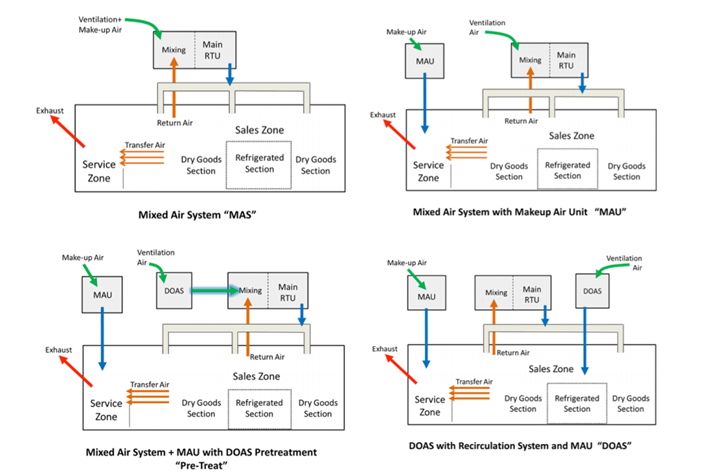

A Mixed Air System (MAS) is the most common climate control method within a grocery store. This is when a rooftop unit (RTU) brings in a quantity of unconditioned OA, mixes it with return air, and then passes it over direct expansion (DX) coils before being distributed to the rest of the store. The disadvantage of this system comes with the energy needed to condition and force the air through multiple RTUs. In fact, standard RTUs can only handle about 20% of OA. For MAS, the supply air must be more than 5x the amount needed when no OA is required. Additionally, there must be a clear flow path between the location in the store where OA is delivered and the place where air is exhausted. If OA is supplied to a sales zone and exhausted in the kitchen, an unobstructed path between the two zones must exist.

Another form of delivering OA for the purpose of climate control is by introducing a Mixed Air System with Make-Up Air Unit (MAU) directly where OA is needed. This will take the cooling loads off the RTUs, thus reducing the energy cost for increased supply air. To do this efficiently, many MAUs will use demand control ventilation to only deliver the necessary amount of OA based on the required exhaust rate. This is seen in kitchen areas where smart hood systems, such as Intelli-Hood®, sense the level of cooking activity and instruct the exhaust fans to only operate as fast as necessary. An MAS will still be used to condition the refrigeration sections and produce; however, the mixing RTUs will require less tonnage since they will be handling less OA.

Taking a hybrid approach between the MAS and MAU system, Mixed-Air System with a Dedicated Outside Air System (DOAS) Pretreatment seems to offer a more effective and efficient means for introducing OA into supermarkets. This system keeps mixing RTUs and dedicated MAUs but adds a DOAS unit that is designed to handle most of the latent loads, or loads concerned with measuring humidity. This eliminates the need for the main RTUs to dehumidify as much, decreasing them in cooling size, and allowing for a greater airflow per ton ratio. This also reduces the supply air needed by each RTU that slows fan speeds, saving energy.

Finally, that brings us to a Recirculation System, which is the strategy of providing conditioned OA directly to refrigerated sections while recirculating air in produce and dry goods sections. Recirculation offers the best way of controlling humidity and pressure for the respective zones. This allows for the mixing RTUs to only deliver the minimum amount of airflow to maintain comfort levels as opposed to the large amount of airflow required to dehumidify with pre-treatment.

Maintaining a Healthy Store

As can be seen, there are multiple ways to control climate within any given supermarket. Melink Corporation offers many solutions to balancing, monitoring, and controlling air in buildings. Whether energy efficiency or simplicity is at the forefront, maintaining a healthy environment to keep these essential stores open ensures our pantries can be kept stocked.

Concerned about the climate in your facility? Drop me a comment below or call (513) 965-7300.

Source & Photo Credit:

Clark, J. (2015). Energy-Efficient Supermarket Heating, Ventilation, and Air Conditioning in Humid Climates in the United States (pp. 1-35, Tech.). Golden, CO: National Renewable Energy Laboratory.